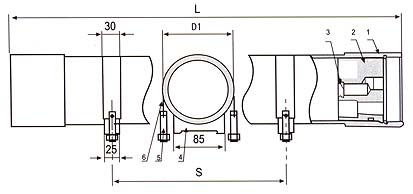

4"end,side opening membrane housing |

|

|

L-length of

pressure container, different from the specification and

quantity of

film element.

D1- OD of pressure container

S-supporting span of pressure container |

| Marked number |

Qty |

Name of part |

Material/remarks |

| 1 |

1 |

Pressure case |

epoxy gfrp/fiber twisted |

| 2 |

2 |

End

plate |

ABS |

| 3 |

2 |

Original/concentration |

304

stainless steel |

| 4 |

2 |

0 shape |

GB 3452.1-8 |

| 5 |

2 |

bundle belt |

stainless steel strip |

| 6 |

4 |

locking bolt |

GB 3098.6-86 |

| 7 |

2 |

bolt seat |

synthetic rubber |

| 8 |

4 |

buffer |

304

stainless steel |

|

Pressure of work |

Qty of section |

L mm |

D1 mm |

S mm |

| 300PSI |

1 |

1134 |

112 |

610 |

| 2 |

2151 |

112 |

1350 |

| 3 |

3167 |

112 |

1960 |

| 4 |

4183 |

112 |

1580x2 |

| 1000PSI |

1 |

1195 |

114 |

610 |

| 2 |

2205 |

114 |

1350 |

| 3 |

3215 |

114 |

1960 |

| 4 |

4225 |

114 |

1580x2 |

|

Technical

requirements:

The fabricating method of membrane housing should be in accordance with

JC692-1998;

The design pressure of membrane housing is 1000PSI and the permitted scope

of work temperature is

7~49

The leakage test of membrane housing adapts hydraulic test. The test

pressure is 1.2 times of the design

pressure. |